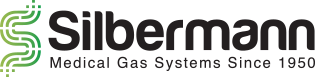

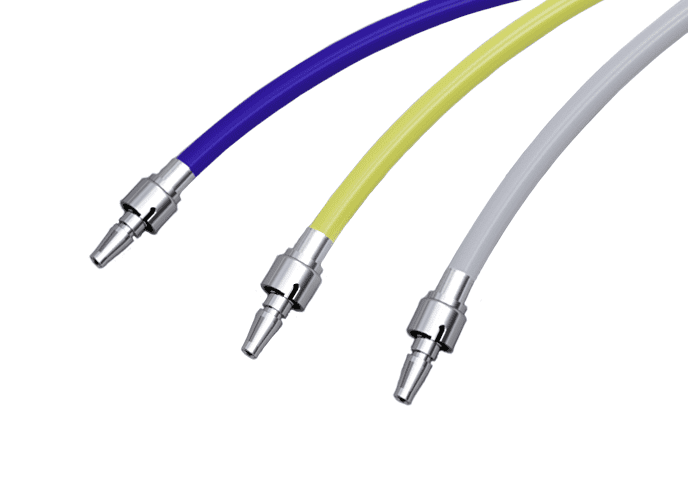

Tipo DIN 13260-2

Nuestras tomas de gases medicinales son diseñadas y fabricadas para que duren y garanticen un flujo constante y seguro de los gases medicinales, para el paciente y los equipos medicinales

Flujo y fugas de todas las tomas de gas son 100% probadas. Posteriormente las tomas de oxígeno son limpiadas antes de ser despachadas.

Nuestras tomas están diseñadas por diseñadores industriales para garantizar una apariencia y entorno atractivos y agradables para el paciente y el personal médico.

Descargas:

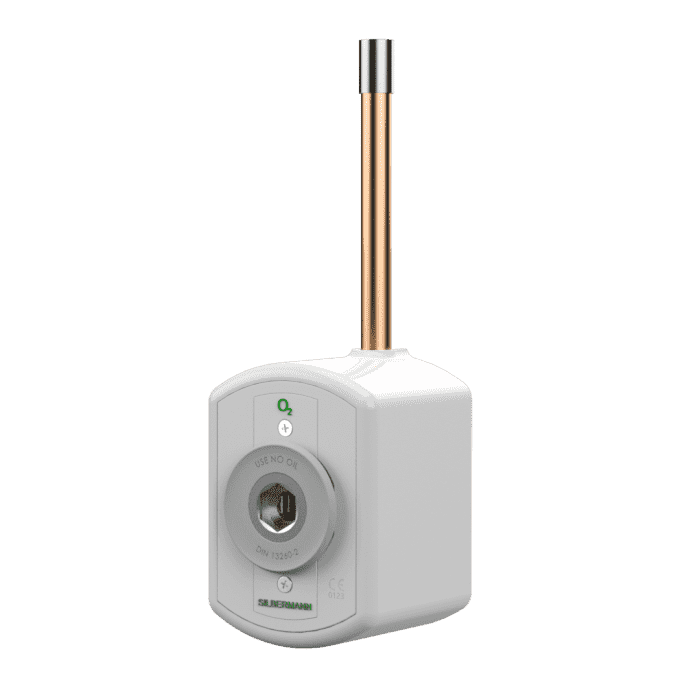

■ Accepts DIN 13260-2 gas specific adapters.

■ All medical gas outlets are 100% hydrostatic tested for leaks.

The outlets are factory assembled, degreased and cleaned

for medical gas service.

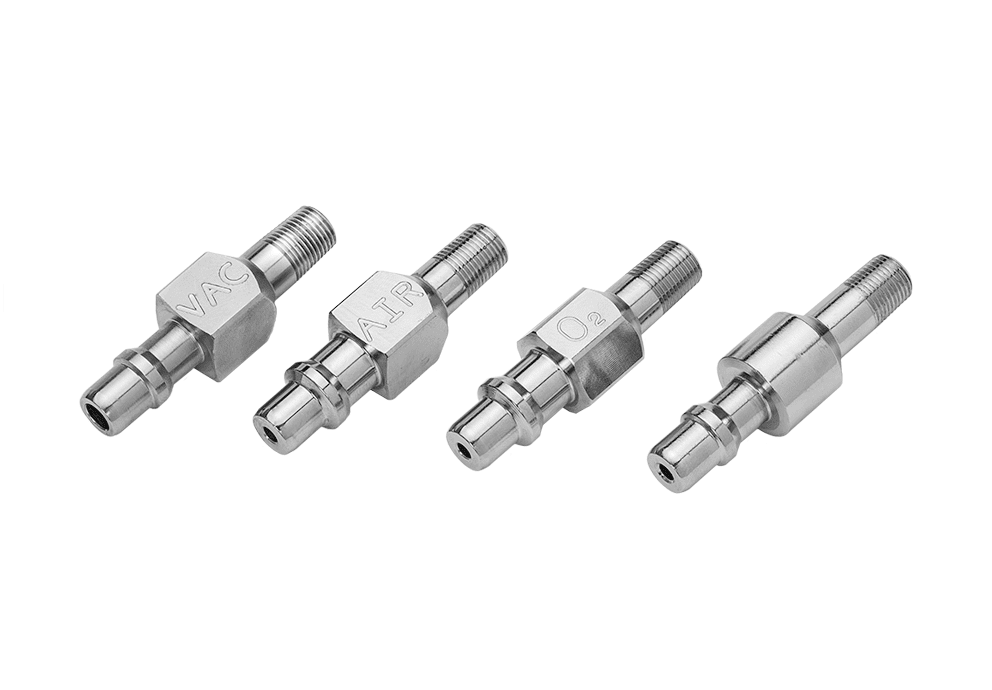

■ Indexed to eliminate interchangeability of gas services.

■ 360 deg swivel inlet pipe for ease of installation.

■ Double position allowing parking of male adapter in the outlet.

■ Low maintenance due to use of VITON seals in front assembly (latch value).

Medical Gas System Standards:

■ NFPA99 & EN ISO 7396-1 requirements.

Applicable Standards:

■ ISO 9170-1, DIN 13260-2.

Silbermann's Quality Management System:

■ CE marked by the notiied body TÜV-SÜD.

■ The medical gas outlet shall be SILBERMANN DIN type

manufactured according to ISO 9170-1 DIN 13260-2.

■ The outlet shall be gas speciic by indexing each front service

panel to a gas speciic pin indexed rough-in module.

■ The outlet of positive and negative pressure

shall consist of a primary and secondary

check valves to allow testing and on-line maintenance.

■ Outlet shall be manufactured with 175 mm

long, type K, 12.7 mm (1/2”) OD copper pipe.

Rough-in pipe shall be silver brazed to

the outlet body.

■ With the rough-in mounted, the outlet shall be

depth adjustable to compensate for various wall thicknesses.

■ The quick connect outlet shall comply with ISO 9170-1

standard type and accept only corresponding DIN 13260-2

Gas Speciic Adapter.

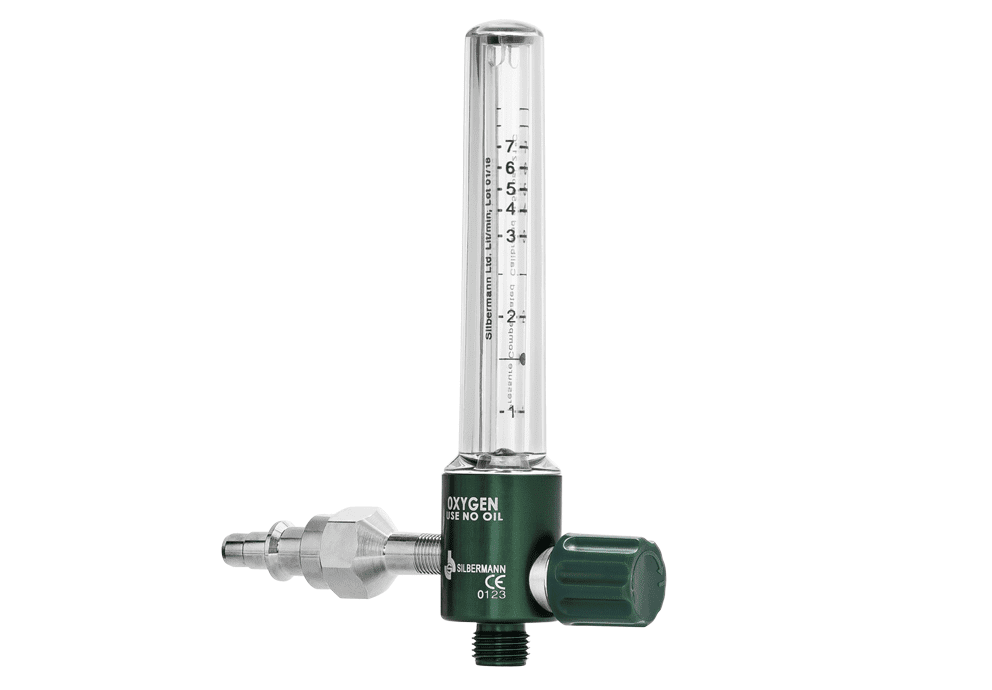

■ Pressure drop of less than 20 Kpa through the outlet

at 120 LPM and 350 Kpa (3.5 Bar) inlet pressure.

■ When fully open, the outlet allows a low of up

to 600LPM and pressure of 400 KPa (4 Bars).